Tire Pyrolysis Market Forecast for Asia in 2026

The tire pyrolysis market in Asia is poised for significant growth by 2026, driven by the region’s rising waste management challenges, increasing environmental regulations, and growing demand for sustainable energy solutions. Tire pyrolysis, which converts waste tires into valuable byproducts such as oil, carbon black, and gas, is becoming a key technology for addressing both environmental concerns and resource shortages. As the demand for cleaner energy and circular economy

Compliance Assurance Frameworks for Oily Sludge Pyrolysis Operations

Oily sludge pyrolysis has become a strategically important treatment pathway for hazardous residues generated by petroleum extraction, storage, and refining activities. These sludges contain complex mixtures of hydrocarbons, water, solids, and trace contaminants, posing persistent environmental and regulatory challenges. While pyrolysis offers volume reduction and resource recovery advantages, compliance assurance remains the defining factor for operational legitimacy. A well

Managing Waxy Residue in Plastic Pyrolysis

In the field of plastic recycling, pyrolysis has emerged as a promising technology for converting plastic waste into valuable products like oils, gases, and solid residues. However, one of the challenges faced by operators of a pyrolysis plant is the formation of waxy residues during the thermal decomposition of plastics. These waxy byproducts, often referred to as "wax," can pose significant issues in both the process and product quality. Effectively managing and mitigating

Enhancing Fertilizer Efficiency through Biochar-Organic Compost Integration

The integration of biochar with organic fertilizer represents a significant advancement in sustainable soil fertility management. By combining the nutrient density of organic compost with the structural and adsorptive properties of biochar produced in a pyrolysis plant , the resulting material provides a synergistic enhancement in nutrient retention, microbial vitality, and carbon stability. This hybrid amendment supports higher fertilizer efficiency and offers long-term ecol

Sulfur Management Strategies in Tyre Pyrolysis

The pyrolysis of end-of-life tyres offers a sustainable route for recovering valuable hydrocarbons, carbon black, and steel, yet it introduces a complex challenge—sulfur control. Tyres typically contain 1–2% sulfur, introduced primarily through vulcanization agents such as zinc oxide and sulfur compounds. During thermal decomposition, these compounds undergo fragmentation, producing sulfur-bearing gases, tars, and solids that, if unmanaged, can cause severe corrosion, catalys

Moisture Content in Oily Sludge and Its Impact on Pyrolysis Efficiency

Efficient valorization of oily sludge through thermal conversion depends on a delicate interplay of moisture content, feedstock...

Solutions for Coking Issues in Oil Sludge Pyrolysis

Oil sludge, a byproduct of various industrial processes, poses a significant challenge for waste management and environmental...

Economic Viability of Oil Sludge Recovery Using Thermal Desorption Unit

The management of oil-contaminated sludge has evolved significantly with the adoption of thermal desorption units (TDU), which offer a...

Environmental Benefits of Tire Pyrolysis in Waste Valorization

End-of-life tires represent a persistent global waste problem due to their durability, volume, and chemical complexity. Landfilling and...

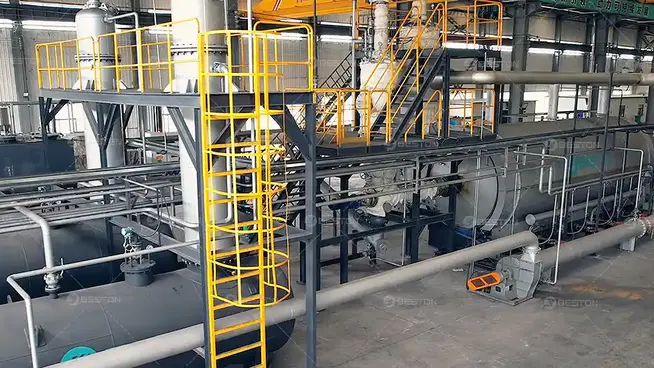

Maximizing Thermal Efficiency in Pyrolysis Reactor Design

Thermal efficiency is a critical performance metric in any pyrolysis reactor. It governs energy consumption, product yield, and overall...