Charcoal Production and Its Expanding Role in the Metallurgical Market

Charcoal production is re-emerging as a structurally important activity within the metallurgical sector. This resurgence is not driven by nostalgia or small-scale tradition, but by pragmatic industrial forces. Metallurgy faces mounting pressure to decarbonize high-temperature processes while preserving reduction efficiency and material quality. Charcoal, as a biogenic carbon source, occupies a distinct position between conventional fossil reductants and emerging synthetic alt

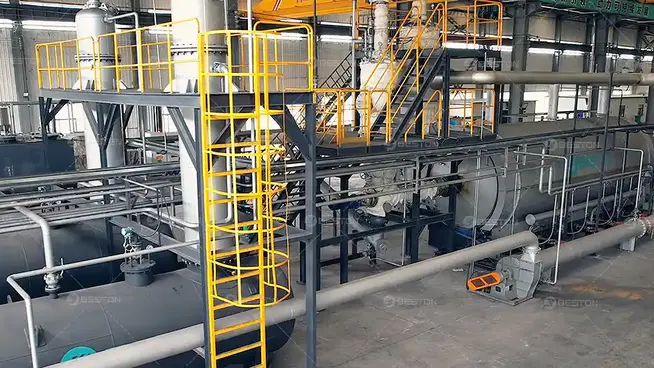

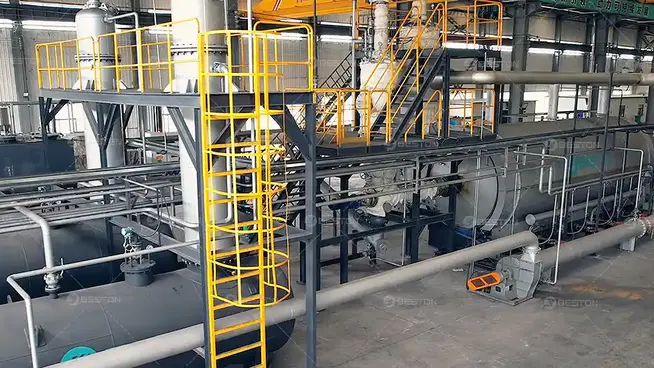

Tire Pyrolysis Market Forecast for Asia in 2026

The tire pyrolysis market in Asia is poised for significant growth by 2026, driven by the region’s rising waste management challenges, increasing environmental regulations, and growing demand for sustainable energy solutions. Tire pyrolysis, which converts waste tires into valuable byproducts such as oil, carbon black, and gas, is becoming a key technology for addressing both environmental concerns and resource shortages. As the demand for cleaner energy and circular economy

Challenges in the Production of Coconut Shell Charcoal

Coconut shell charcoal production has gained significant attention as an eco-friendly alternative to traditional charcoal due to its high carbon content, efficient energy yield, and applications in various industries such as metallurgy, agriculture, and environmental protection. However, the production process is not without its technical challenges. These challenges arise from the inherent properties of coconut shells, the intricacies of pyrolysis technology, and the demand

Temporal Permanence Debates in Biochar Carbon Removal

Biochar carbon removal has gained prominence as a measurable and scalable pathway within the broader carbon dioxide removal landscape. Its central premise is deceptively simple: convert biomass into a stable carbon-rich solid and store it in soils or other durable reservoirs. The controversy begins when time enters the equation. How long the carbon remains sequestered, and how confidently that duration can be claimed, remains a point of sustained debate. Carbon Removal and th

Compliance Assurance Frameworks for Oily Sludge Pyrolysis Operations

Oily sludge pyrolysis has become a strategically important treatment pathway for hazardous residues generated by petroleum extraction, storage, and refining activities. These sludges contain complex mixtures of hydrocarbons, water, solids, and trace contaminants, posing persistent environmental and regulatory challenges. While pyrolysis offers volume reduction and resource recovery advantages, compliance assurance remains the defining factor for operational legitimacy. A well

Essential Maintenance Practices for Biochar Machine Operations

Maintaining a biochar machine in optimal condition is critical for achieving consistent production efficiency, product quality, and operational longevity. Unlike conventional equipment, biochar production involves high temperatures, abrasive feedstocks, and continuous thermal cycling, all of which impose unique mechanical and thermal stresses. A structured maintenance regimen not only minimizes downtime but also mitigates safety risks inherent in high-temperature operations.

Ensuring Wood Charcoal Quality Through Controlled Pyrolysis Processe

Wood charcoal quality hinges on a series of thermochemical transformations that occur during pyrolysis. The structural integrity, carbon density, volatile content, and calorific performance of the final product are all shaped by parameters embedded within the thermal decomposition pathway. Within a modern pyrolysis plant, precision control mechanisms make it possible to regulate these parameters and thereby guarantee consistent, high-grade charcoal output. Stable thermal envi

Managing Waxy Residue in Plastic Pyrolysis

In the field of plastic recycling, pyrolysis has emerged as a promising technology for converting plastic waste into valuable products like oils, gases, and solid residues. However, one of the challenges faced by operators of a pyrolysis plant is the formation of waxy residues during the thermal decomposition of plastics. These waxy byproducts, often referred to as "wax," can pose significant issues in both the process and product quality. Effectively managing and mitigating

Enhancing Fertilizer Efficiency through Biochar-Organic Compost Integration

The integration of biochar with organic fertilizer represents a significant advancement in sustainable soil fertility management. By combining the nutrient density of organic compost with the structural and adsorptive properties of biochar produced in a pyrolysis plant , the resulting material provides a synergistic enhancement in nutrient retention, microbial vitality, and carbon stability. This hybrid amendment supports higher fertilizer efficiency and offers long-term ecol

Sulfur Management Strategies in Tyre Pyrolysis

The pyrolysis of end-of-life tyres offers a sustainable route for recovering valuable hydrocarbons, carbon black, and steel, yet it introduces a complex challenge—sulfur control. Tyres typically contain 1–2% sulfur, introduced primarily through vulcanization agents such as zinc oxide and sulfur compounds. During thermal decomposition, these compounds undergo fragmentation, producing sulfur-bearing gases, tars, and solids that, if unmanaged, can cause severe corrosion, catalys